Selected Materials - Tatami

Tatami mat shapes rectangle, and composes tatami-doko(inner part) and tatami-omote(tatami-facing). Especially tatami-omote is very important. Depending on its quality and weave pattern, the tatami grade will be decided.

The following procedures show how to produce tatami mat by using high-quality rushes where is made in Bingo Region, Hiroshima pref.

1. |

Prepare thin and long rush which is in improving breeds repeatedly, and multiply a young plant by separating the roots of the mother plant in a severe cold season.

Through the cold season, a lot of new sprouts come out near its roots on May.

To promote growth of the sprouts, mow the 50cm from the top of rushes.

|

|

2. |

On July, those rushes grow up enough to go, therefore, mow them and apply mudding* temporally. Mudding enhances the durability, viscosity, flexibility and brightness remarkably.

And then, dry them out until the autumn comes. |

|

3. |

Check rushes visually to remove bad ones out from good ones before setting into the weaver machine. |

|

4. |

Use dry straws for a tatami-doko(inner part). Choose the similar straws such as hardness, straightness and length, and arrange them to several steps.

|

|

5. |

Weave straws to make a core of tatami-doko(which is called 'Dou-gomo'), compress, and cut them.

Good Dou-gomo has flexibility and should be comfortable for use.

|

|

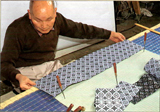

6. |

To make the perfect tatami-mat, measure the size of the room and unite tatami-omote and tatami-doko, and then, cut tatami-omote. Each room has their own tatami mats size to fit. |

|

7.

|

Tighten hemp yarns coming out from the side of tatami-omote(Kamachi-binding), and sew the tatami-fuchi(the edge part of a tatami mat). |

|

|

Through the above processes, tatami mat is finally ready to go. Tatami is produced based on the premise that residents walk around without any shoes. We hope you enjoy its soft feeling of tatami. |

Cooperation: Rush Products Cooperative Association of Hiroshima Prefecture |